WELCOME

ABOUT US

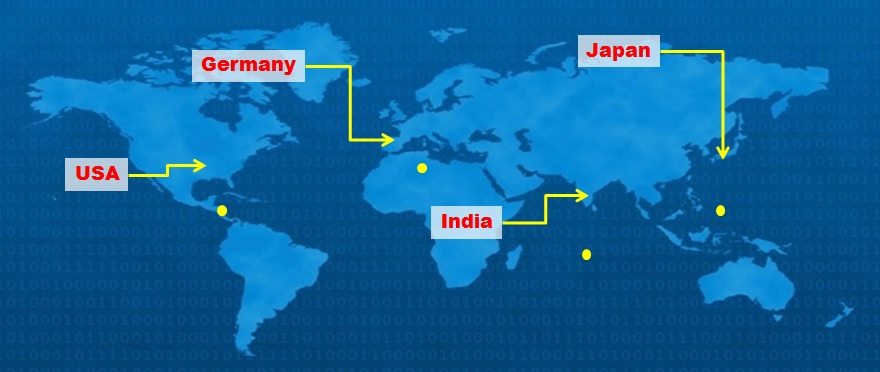

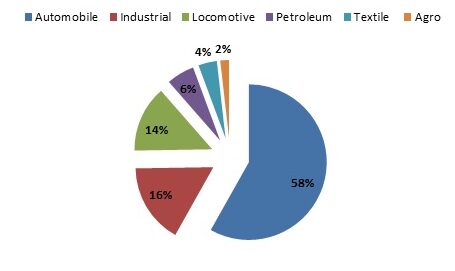

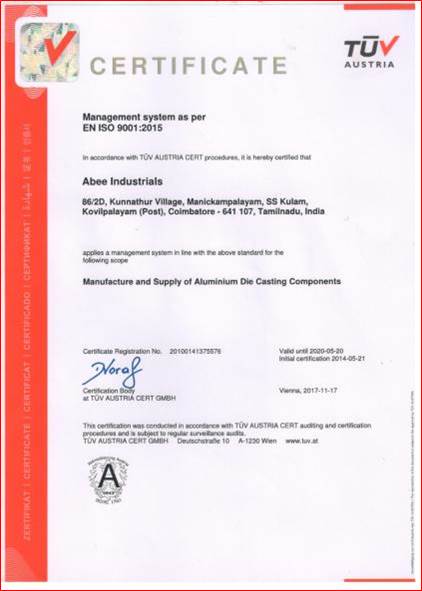

We, Abee Group was established in the year of 1975 in Coimbatore, Tamilnadu. We have a vast range of Aluminium die making, Gravity Die Casting, machining & Foundry pattern designs, sizes and applications on offer. Buyers can benefit from powerful and varied capabilities of these dynamic casting tools, accessories and the products are seamlessly integrable with other existing machinery. These casting product deliver an ideal combination of service excellence, quality and budget friendliness. Our company has professional certification ISO 9001 (TUV-SUD).We are adept at delivering, high utility casting solutions for industrial, agricultural sectors, automotive plants and other requirements.

Technological Excellence

With technological excellence in all streams of manufacturing we cast from 50 gms to 350 kgs castings with melting capacity of 200 MT/month.

- Exploring New Opportunities

- Stepping towards implementing new competitive strategies

- Focus on Brand Identity and Brand Positioning

ABEE Cast Private Limited committed to ensure quality based on the customer Need With continual improvement

We are responsible for quality in every one by enhancing the employees skill with measurable objectives and on-time delivery to the customer

- Quality in behaviour

- Quality in Attitude

- Quality in Governance

SERVICES WE COVER

OUR CAPABILITIES

We have world class facilities for delivering end to end solution for castings. Currently our group is established a fully automated aluminium casting unit with 50,000+ sq ft at Coimbatore,India to meet customer requirement with quality and on-time delivery. We have a well-trained team which comprise of young and well qualified engineers each specialized in different departments. We have separate units as per functionalities including Administrative department, Sourcing , NPD , Manufacturing , Assembly , Quality testing , Packaging & Despatch departments.

By using premium grade casting materials (metals and alloys) and following economical, efficient work flows, we are able to prepare casting products of intricate and increasingly innovative shapes for stronger, better mechanical performances. Flowing designs are incorporated for greater convenience. The growing role of 3D modeling technology helps us to establish uniformly smooth collaborations with our clients. This ensures higher mechanical precision and accuracy and minimizes the uncertainty factor.

The in-house experts have the necessary skill and technical acumen to design casting products that are dimensionally accurate and have top notch consistency. Quality monitoring and checks are performed throughout the production process to ensure flawless, precision designs and high quality surface finishes.

FIRST-CLASS DIE-CAST ALUMINIUM PRODUCTS

OUR PROCESS FOR THE PRODUCTION

Customer will float the requirement to us.

We have well experience Team to study the tooling machining die casting and other requirement to check feasibility.

After feasibility Study and customer approval. We start team design and development activity with our expert knowledge of metals and casting methods to find the best value in a quality casting. We do follow these guidelines like Using Consistent Wall Thickness, Upsizing Fillet Radii, Include Ribs and Bosses, Using Pockets, Testing and Trouble Shooting, Making Improvements to release the final product with for best design possible, With time line.

The purpose of the sample submission form is to dictate the documentation needed to demonstrate the traceability of the sample is maintained throughout the receipt, testing, packing and storage process.

We send the pilot batch of Product Manufactured during the Development Program at a minim volume sufficient for process development, stability testing and related quality testing Customer required by the Development Program.

We Post the Pilot Batch; we would get a final approval from the Customer for the next process of Manufacturing.

During Die casting manufacturing process we follow all the Procedures which was defined at the time of pilot batch.

The next Process of Die casting, we involve in the Post Casting Operations like Runner Cutting, Belt Grinding and Felting Processes. we follow all the Procedures which was defined at the time of pilot batch.

Heat treatment is carried out Depending on the specific requirement of the customer. We have closed loop system to control the temperature and time to achieve the required harden and Mechanical Properties.

Shot Blasting is carried out Depending on the requirement of the customer it is to improve the surface finish and for stress reliving in the casting.

We use precision Machining to achieve geometrical tolerances. By using compensation tools we improve the cycle time.

Surface Treatment process carried out Depending on the requirement of the customer it is to improve the surface finish Anodizing and cromotazing.

Painting is done based on customer requirement. After surface treatment we do Painting, Powder coating, E-Coating.

After completion of all process we do inspection as defined in Control plan.

The Final Step is we do quality packing and Flawless dispatch through our logistics department.

CLIENTS

OUR CUSTOMERS